After using Lundahl transformers and chokes for about twenty years, it was about time to visit their factory.

Lundahl Transformers AB was founded 1958 by Per Lundahl's parents Gunnel and Lars. After running the operations in the basement of their house in Stockholm for a few years, they moved to Norrtälje and opened the factory there. Norrtälje is a beautiful city about 70km north of Stockholm.

Situated at the coast, Norrtälje has direct access to the baltic sea:

Houses are built in the typical swedish style:

The Lundahl factory is in Tibeliusgatan.

The factory is also built in the typical swedish fashion, blending in nicely with the town:

Inside everything is meticulously organised. Manufacturing is following well thought out processes which ensure the high consistency which Lundahl is famous for.

The floor with winding machinery:

All the machines are developed, built, programmed and maintained in house!

6 coils are wound at once. See the machine in action in this short video:

Most of the delicate work of winding and assembly is carried out by women.

pre wound coils, ready for the next assembly step:

A trademark of Lundahl is the dual coil construction. Each transformer is made of two identical coils:

Adding the core:

In this case stacked laminations.

The assembled transformer, ready to be put into the housing:

After the wire is soldered to the pins, the assembly is housed in the mu metal cans and labelled:

Lundahl doesn't like to leave things up to chance, hence as much as possible is done in house. While other manufacturers would source housings, Lundahl makes them, again using own machinery:

A spool feeds a strip of mu metal into the machine which bends it into the shape without destroying the permeability.

A typical example of the details which are taken care of is this rig with a bottle of alcohol which cleans the surface before the metal is bent and welded into shape:

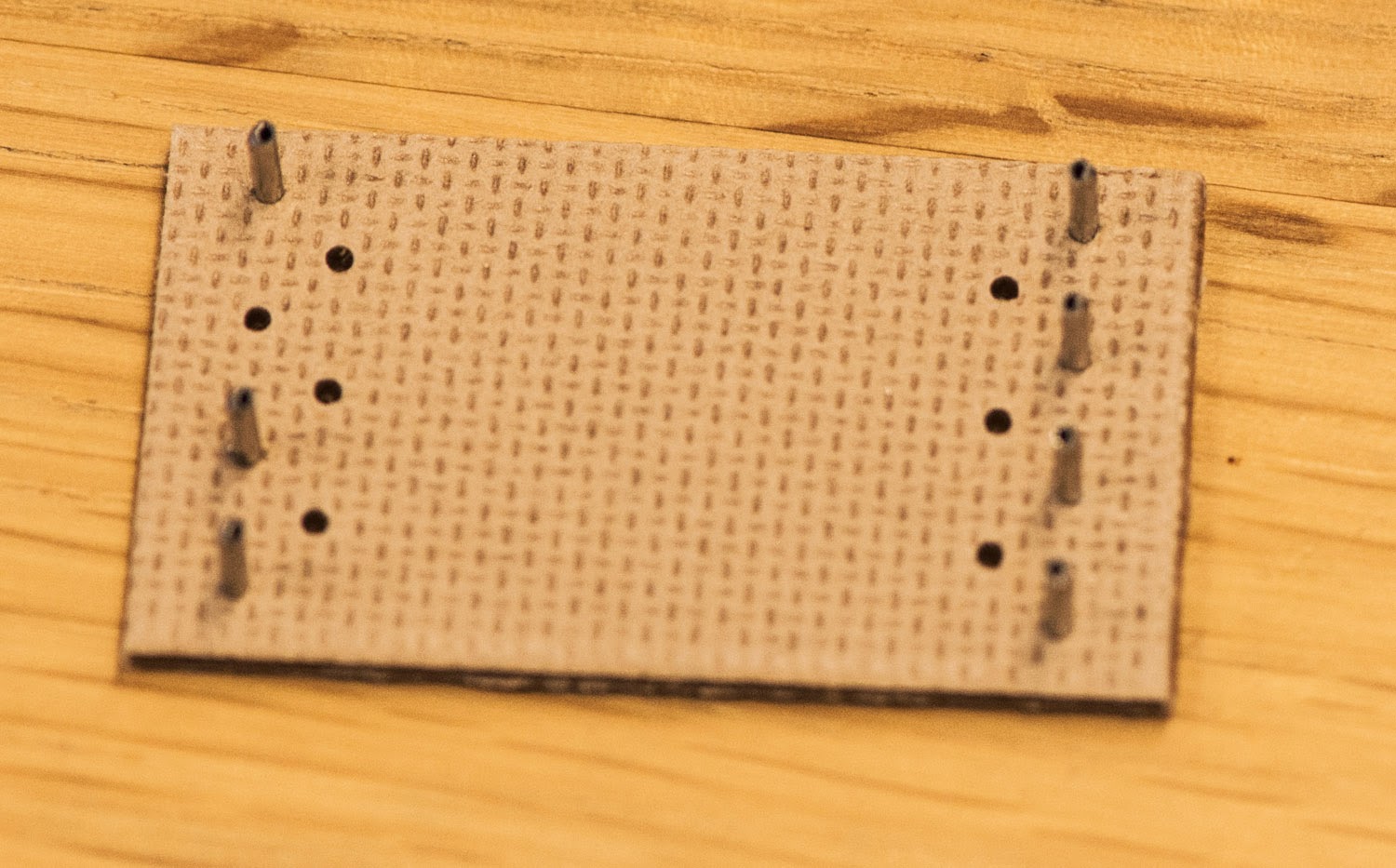

The terminal pins are another example of the impressive in house capabilities.

What seems like a rather mundane item is not sourced from outside but made to Lundahls own quality standards:

This machine cuts pieces from metal strips fed by spools and shapes them into hollow pins which take the copper wire from the transformers coils.

Chokes, interstage and output transformers are wound on the well known C cores. Lundahl receives the high flux grain oriented metal for the c cores in such large drums:

This is then cut into the widths for the different transformer types:

Wet polishing after cutting:

Cores are wound from this strip.

Wound cores:

Then the cores are cut to obtain two separate 'C' shaped parts:

The corners are carefully chamfered and the surface is meticulously polished to obtain a consistent and precise air gap.

Coils and cores for C-core transformers and chokes are stored and assembled just before an order is shipped.

A coil for output transformers:

Pre assembled choke coils, with paper insulation:

The gap is defined at final assembly by the use of foil with appropriate thickness:

This way single ended transformers can be made with custom air gaps for a wide range of currents.

Small transformers in mu-metal housing are stocked in good quantities for the most commonly ordered types:

With nothing left to chance during each production step, of course there are detailed quality checks done on every single transformer or choke.

A whole set of measurements is done on each part, for example distortion and inductance tests.

Parts ready for shipment:

The photos above only show a part of the facilities. Here are a few others. For example the room for vacuum impregnation:

The annealing furnace:

Part of the wire stock:

For maintaining all the machinery and to build new ones if required, there is a fully equipped metal shop:

It has been a great experience to get a real life impression of the extremely structured work flow and the atmosphere of the highly concentrated and motivated people who make these products. I'd like to thank the staff of Lundahl Transformers for the great day. And especially thanks to Per Lundahl for the hospitality.

Keep on the great work!

Best regards

Thomas

Nice post!

ReplyDeleteThanks for this visiting to the factory of high quality transformers.

SOTA!

ReplyDeleteIt is fascinating to see where my 8 pieces of "iron" come from.

ReplyDeleteThank you, for this great report!

Very nice reporting, Thomas!

ReplyDeleteI want to buy some now.

TonyB

Thank you for sharing your visit - or should I say "pilgrimage"? The fantastic quality and somewhat idiosyncratic mechanical style of their transformers prepared me for what I saw - excellent and highly detailed craftsmanship. Not a surprise, but still nice to see!

ReplyDeleteWell tought! Nice spot. The visit of the factory is interesting. It gives a picture of the maker behind the product.

ReplyDeletePierre G.

Appears to maintain very high quality standards and consistency.

ReplyDelete