Earlier this year, I already introduced the modular preamplifier concept. Here a post about the first modular phonostage in this style. The phono got broken up into input and output gain stages and separate MC step up and EQ units to be able to experiment with different gain modules. One of the ideas behind this was to experiment with directly heated triodes in the phono section. As a first step the phono output stage can be changed to DHT. And later maybe the input stage as well, but the usually high mircrophonics of DHTs might prevent this.

The first circuit draft of a directly heated gain stage is shown above. The plan is to use the 841 as the gain element, because it is one of the few DHTs with considerably high amplifaciotn factor. Since it has a rather high plate resistance, it will be choke loaded and DC coupled to a 801 which will drive a step down line output transformer for low output impedance. To minimize capacitors in the signal path, the 841 will use filament bias. The output stage uses an ultra path cap from B+ to cathode (filament) of the 801. The other caps are there for decoupling and are not directly in the signal path. The 841 will run at about 5mA. Since the 801 operates at a higher current, a bypass resistor of about 47k is needed for the current difference. Final values need to be checked and if necessary adjusted once the circuit is built.

The power supplies will follow my usual approach with passive choke filtering and tube rectification. Since this is meant for phono use, the usual LCL approach for the filaments will not be sufficient, so another LC stage needs to be added which ends up in 3 chokes per tube, 12 total! 8 of these chokes will be placed in the PSU unit and the final chokes in the preamp section. High voltage will be rectified with a TV Damper bridge, followed by LCLCLC filtering and the final LC decoupling separate per channel in the preamp section.

This is a lot of iron, so 3 chassis are needed. Separate PSUs for filament supplies and high voltage. Even with the three chassis, there are too many components to use the enclosed wooden frames, so some parts need to be placed on top, similar to the 10Y preamplifier

The initial construction steps for the filament supply chassis. Power transformers placed on the top:

The filament transformer which is used is described here. Due to the high voltage drop through the chokes, 1 per tube is not enough. 2 more transformers are added. The separate secondaries of those are shared between two supplies.

The initial wiring of the filament transformers:

The filament chokes are mounted on sub plates which will be placed inside the wood chassis:

The rectifier bridges using Schottky diodes are directly soldered to the input choke along with the filter caps:

The high voltage supply will be constructed in a similar style, transformers, input choke and rectifiers placed on top of the chassis:

Since the circuit uses 800V B+, two transformers are needed with the secondaries in series. To keep the heater to cathode voltages for the rectifiers within specs, 3 separate heater windings are required. Since each of the B+ transformers has only one heater winding, a separate heater transformer is added for the third one.

The initial wiring:

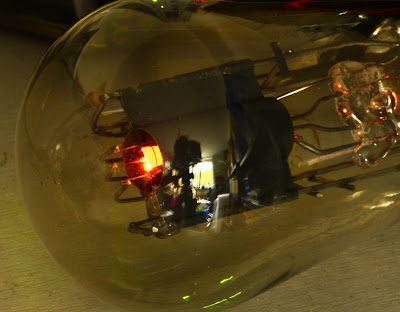

And finally the first construction steps of the signal chassis. Sockets mounted on vibration damped sub assemblies. The capacitors are Sprague paper in oil types with 2kV voltage rating. Here painted in white:

The initial signal wiring:

The filament bias resistors are at the front. The connection between them serves as star ground point. All signal wiring is done with solid core silver wire.

This is probably one of my crazier projects. You might wonder why so much effort and why not try smaller DHTs which need less filament current. And why no regulated supplies instead of those heaps of iron. Such an approach might follow later. First I want to create the ultimate DHT phonostage. And that has to use tubes with thoriated tungsten filaments in my book. While there are good solutions for filament regulators, I still prefer the passive approach. Such regulators work best if preceeded with a good supply with choke input filter anyways, so staying completely passive is not that much more in terms of parts.

Stay tuned for updates as the construction of this DHT gain stage progresses.

Best regards

Thomas